SOP for Calibration Total Organic Carbon (TOC) Analyzer

1.0 Objective

To check the performance of Total Organic Carbon Analyzer.

2.0 Scope

This procedure is applicable to calibrate Total Organic Carbon Analyzer.

[ads id="ads1"]

3.0 Responsibility

3.1 Doing: Technical Assistant

3.2 Checking: Executive /Manager

4.0 Accountability

Head of the Department

5.0 Procedure

5.1 Clean the instrument with a dry cotton cloth.

5.2 Operate the instrument as per S.O.P.

5.3 Performance check of TOC

5.3.1 TC : Dissolve 0.5950 gm. of sucrose in 500 ml of water to get 500 ppm of carbon and further dilute with water to get final concentration 250 ppb, 500 ppb and 750 ppb of carbon.

[ads id="ads1"]

5.3.2 IC : Dissolve 0.875 gm NaHCO3 and 1.1025 gm.of Na2CO3 in 500 ml of water to get 500 ppm IC standard and further dilute with waters to get final concentration 250 ppb, 500 ppb and 750 ppb of carbon

5.3.3 NPOC : Dissolve 0.5950 gm.of sucrose in 500 ml of water to get 500 ppm of carbon and further dilute with water to get final concentration 250 ppb, 500 ppb and 750 ppb of carbon. Add 1ml 2N HCl in 250, 500, 550 ppb solution.

5.3.4 Analyse the samples of step 5.3.1, 5.3.2. and check the linearity, report in Annexure-I.

5.4 For system suitability

5.4.1 Preparation of 500 ppb benzoquinone solution :

Dissolve 0.375 gm. benzoquinone in 500 ml of water to get 500 ppm of carbon and further dilute and analyze with water to get final concentration 500 ppb of carbon and analyze solution as a sample.

5.4.2 Add 1ml of 2N HCl in 500 ppb benzoquinione solution.

5.4.4 Calculate the system suitability by the following calculation.

[ads id="ads1"]

[ Rss-Rw ] Where Rss = Mean area count of 1,4 benzoquinone solution

100X [ ------------] ( 500 ppb of carbon)

[ Rs-Rw ] Rs = Mean area count of sucrose (500 ppb of carbon)

Rw = Mean area count of pure water

5.4.5 Area of Limit :

a. Pure water should be more than 10,000 ( 0.25µcg carbon)

b. System suitability : Between 85% to 115% of theoretical response.

5.4.6 Report the results.

[ads id="ads1"]

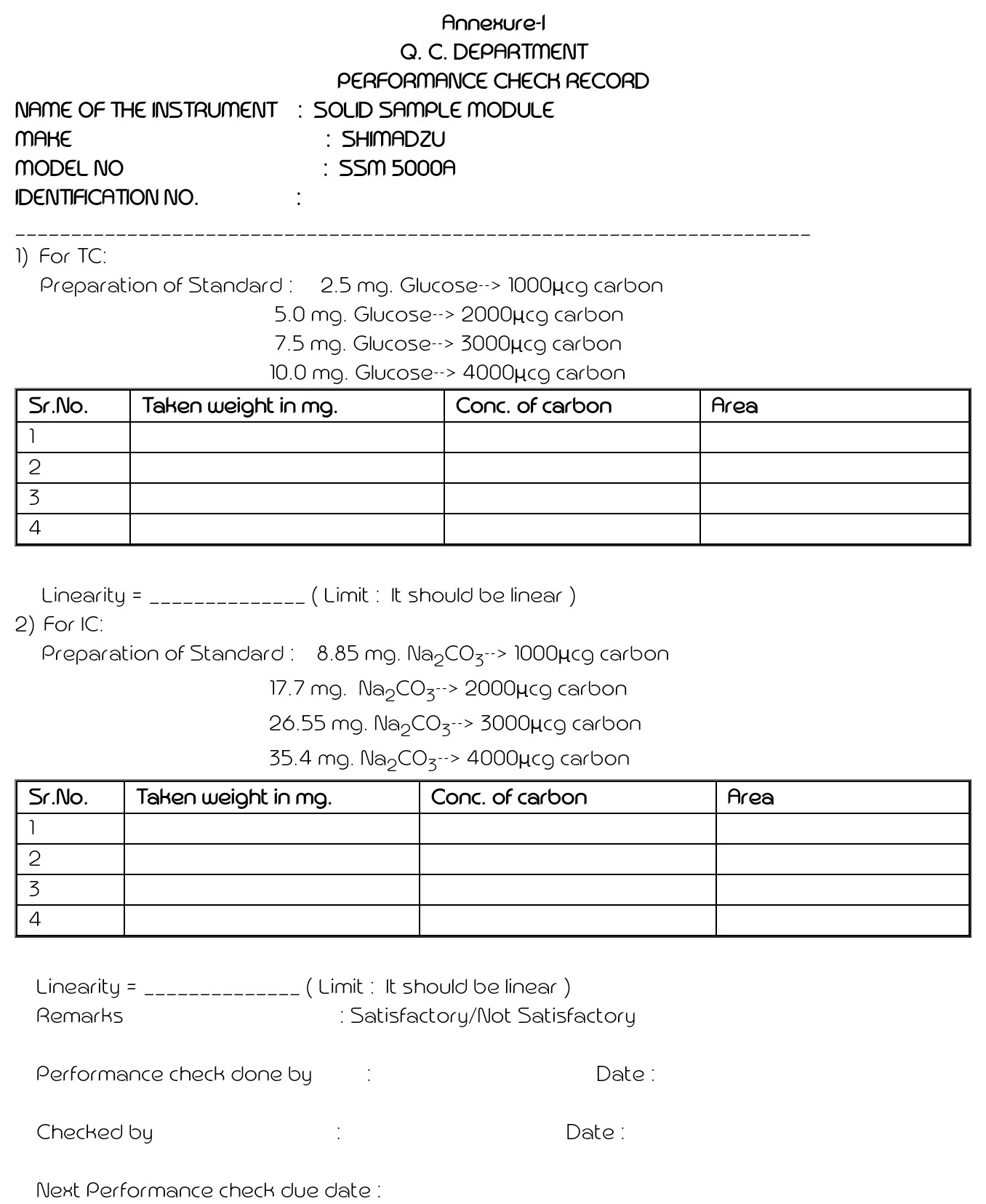

5.5 Performance check of SSM

5.5.1 Total organic carbon :

Take 2.5 mg. of Glucose for 1000 µcg std. carbon

Take 5.0 mg. of Glucose for 2000 µcg std. carbon

Take 7.5 mg. of Glucose for 3000 µcg std. carbon

Take 10.0 mg. of Glucose for 4000 µcg std. carbon

5.5.2 Inorganic carbon :

Take 8.85 mg. of Na2CO3 for 1000 µcg std.carbon

Take 17.7 mg. of Na2CO3 for 2000 µcg std.carbon

[ads id="ads1"]

Take 26.55 mg. of Na2CO3 for3000 µcg std.carbon

5.5.3 Generate 4 point calibration curve for SSMTC and SSMIC with the point of 1000, 2000, 3000, 4000 µcg standards.

5.5.4 In calibration condition “Set the

1st std. concentration as 40 and AMNT 2.5mg

2nd std. concentration as 40 and AMNT 5.0mg

3rd std. concentration as 40 and AMNT 7.5mg

4th std. concentration as 40 and AMNT 10 mg

5.5.5 Set the range as per requirement

5.5.6 Press “O.K” and then press the start button.

5.5.7 After completion all four std. shift to original function in ‘cal curve’ screen before using.

5.5.8 Similarly create a calibration curve for various std.

[ads id="ads1"]

5.5.9 A. Frequency for Total organic carbon :

1. For TC and IC = Once in a six month

2. For NPOC = Once in a month

3. For system suitability: Once in three month

B. Frequency for SSM

TC and IC = Once in a six month

[ads id="ads1"]

6.0 ABBREVIATIONS

6.1 ppb= Parts per billion

6.2 ppm = Parts per million

6.3 µcg = Microgram

6.4 gm =gram

6.5 Na2CO3 = Sodium carbonate

6.6 TC= Total Carbon

6.7 NPOC = Non Purgable Organic Carbon

6.8 IC= Inorganic carbon

[ads id="ads1"]

6.9 SSMTC=Solid Sample Module Total Carbon

6.10 SSMIC=Solid Sample Module Inorganic Carbon

6.11 SSM= Solid Sample Module

6.12 NaHCO3 = Sodium bi carbonate

6.13 API.= Active pharmaceutical ingredient

[ads id="ads1"]